How I Tamed the Supply Chain Beast to Protect My Business Wealth

Running a business means constantly juggling costs, deliveries, and cash flow. I learned the hard way that a weak supply chain can drain profits fast. After one supplier delay wiped out my margins, I dug deep into smarter ways to manage inventory, partnerships, and risk. What I discovered wasn’t about spending more—it was about thinking differently. This is how I turned supply chain chaos into a wealth-preserving machine, and why every entrepreneur should see their supply chain as a financial tool, not just a logistics problem.

The Hidden Cost of a Broken Link

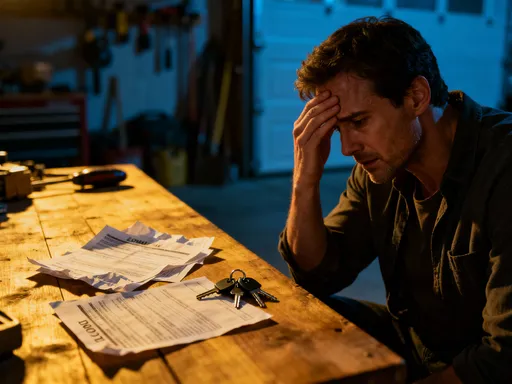

Many business owners treat supply chain issues as operational nuisances rather than financial threats. But a single broken link can trigger a cascade of financial consequences that erode wealth silently and steadily. I once experienced a three-week delay in receiving a key raw material due to a supplier’s production halt. At first, I assumed it was an isolated incident—a minor setback. But the ripple effects were far worse than expected. My production line stalled, customer orders were pushed back, and I had to expedite shipments at triple the usual cost to meet deadlines. By the time operations normalized, I had lost nearly 18% of that quarter’s projected profit. This wasn’t just a logistics failure; it was a direct hit to my bottom line.

What made the situation worse was how much capital was trapped during the disruption. I had already paid for materials that weren’t delivered, and finished goods sat unsold because I couldn’t fulfill bulk orders. Meanwhile, fixed costs like rent, payroll, and utilities continued to accumulate. Cash flow, the lifeblood of any small business, dried up overnight. I began to track every hidden expense tied to supply chain inefficiencies: storage overages from overordering, emergency freight charges, labor idle time, and even the cost of damaged customer relationships. When I tallied everything, the real cost of that single delay was over five times the original invoice value. It was a wake-up call.

This experience taught me that supply chain stability is not just about timely deliveries—it’s about financial resilience. Every delay, miscommunication, or quality issue carries a dollar value, often buried in overhead or written off as “bad luck.” But when viewed through a financial lens, these inefficiencies represent preventable wealth erosion. Businesses that fail to recognize this are essentially leaking money month after month. The truth is, a fragile supply chain acts like a slow leak in a boat—you might not notice it at first, but over time, it can sink your entire operation. Protecting your business wealth starts with acknowledging that every supply chain decision is, at its core, a financial decision.

From Firefighting to Forecasting

For years, I operated in crisis mode. A customer placed a large order? I scrambled to secure materials. Sales dipped? I slashed production without data to guide me. This reactive approach left me vulnerable to constant swings in inventory levels and cash flow. I was always one step behind, putting out fires instead of building a stable foundation. The turning point came when I realized that forecasting wasn’t just for large corporations with teams of analysts—it was a practical, accessible tool for any business serious about financial control.

I started by analyzing two years of sales data, breaking it down by season, product line, and customer segment. What emerged were clear demand cycles I had previously overlooked. For example, one product consistently spiked in sales every spring, yet I had been ordering it based on gut feeling, often running out or overstocking. With this insight, I created a simple forecasting model that aligned purchase orders with historical trends and upcoming marketing campaigns. I also began sharing anonymized sales data with key suppliers, allowing them to anticipate my needs and adjust their production schedules accordingly. This transparency improved lead time accuracy and reduced the need for last-minute orders.

The financial benefits were immediate. By aligning inventory with actual demand, I cut overstocking by 42% within six months. Stockouts dropped by more than half, which meant fewer lost sales and fewer emergency shipments. Most importantly, less capital was tied up in idle inventory, freeing up working capital for other uses. I redirected those savings into product development and customer service improvements, both of which boosted long-term profitability. Forecasting didn’t eliminate uncertainty, but it transformed uncertainty from a threat into a manageable variable. It shifted my mindset from reacting to planning, and that shift became one of the most powerful wealth-preserving strategies I’ve ever implemented.

Building Supplier Relationships That Pay Off

In the early days, I treated suppliers as transactional partners—vendors to be negotiated with, not allies to be cultivated. I focused solely on price, switching providers whenever I found a cheaper option. But this approach backfired. Lower prices often came with lower reliability, and I paid the difference in delays, quality issues, and hidden costs. I finally realized that the cheapest supplier isn’t always the most cost-effective. The real value lies in reliability, communication, and partnership.

I began restructuring my supplier relationships with a long-term financial perspective. Instead of demanding the lowest price, I asked for better terms: extended payment windows, volume flexibility, and priority fulfillment during peak seasons. In exchange, I committed to consistent order volumes and timely payments. One key supplier agreed to a 60-day net payment term, which gave me crucial breathing room in cash flow. Another offered to hold safety stock for me at their warehouse, reducing my storage costs and allowing me to order in smaller, more frequent batches. These weren’t favors—they were strategic agreements that strengthened both businesses.

I also diversified my supplier base to reduce dependency on any single source. I identified two to three reliable providers for each critical component, ensuring that if one faced disruptions, I had alternatives ready. This wasn’t about redundancy for its own sake—it was about risk mitigation. When a major storm disrupted shipping in one region, my backup supplier was able to step in within 48 hours, preventing any production delays. These relationships didn’t develop overnight, but over time, they became a form of financial insurance. Strong supplier partnerships don’t generate direct revenue, but they prevent costly disruptions, stabilize cash flow, and create operational flexibility—all of which contribute directly to wealth preservation.

Inventory as a Financial Lever, Not a Burden

For too long, I saw inventory as a necessary cost—something I had to carry but couldn’t afford to overdo. I either had too much, tying up cash, or too little, missing sales opportunities. It felt like a lose-lose situation. But after studying lean business models, I realized that inventory, when managed strategically, isn’t a burden—it’s a financial lever. The goal isn’t to minimize inventory at all costs, but to optimize it in a way that supports cash flow, reduces risk, and enhances profitability.

I adopted a modified just-in-time (JIT) approach tailored to my business size and industry. Instead of ordering months in advance, I worked with suppliers to shorten lead times and order in smaller, more frequent batches. This reduced my average inventory holding period by 35%. I also implemented cycle counting and real-time inventory tracking using affordable cloud-based software. These tools helped me identify slow-moving items, reduce shrinkage, and eliminate the guesswork in reordering. Accuracy improved, and so did my confidence in making financial decisions based on inventory data.

The impact on cash flow was dramatic. By reducing excess stock, I freed up over $78,000 in working capital within a year—money that had been sitting on shelves instead of earning returns. I reinvested those funds into higher-margin product lines and digital marketing, both of which drove revenue growth. More importantly, I gained agility. When market demand shifted, I could adapt quickly without being stuck with obsolete inventory. Inventory management stopped being a reactive chore and became a proactive financial strategy. It taught me that every dollar tied up in stock is a dollar not working for you—and that managing inventory wisely is one of the most direct ways to protect and grow business wealth.

Tech Tools That Actually Move the Needle

I won’t lie—I was skeptical about technology at first. I tried several expensive systems that promised to revolutionize my operations but ended up being too complex, poorly integrated, or simply unnecessary. I wasted time and money on tools that didn’t deliver. But after stepping back and identifying my real pain points, I discovered that a few well-chosen technologies made a measurable difference. The key wasn’t sophistication—it was simplicity, usability, and alignment with financial goals.

One of the most impactful tools I adopted was inventory management software with automated reorder points. It monitored stock levels in real time and triggered purchase orders when supplies reached a predetermined threshold. This eliminated manual tracking errors and prevented both overordering and stockouts. I also integrated a cloud-based platform that allowed me to share inventory and shipment data securely with suppliers and logistics partners. This visibility improved coordination, reduced miscommunication, and cut lead times by an average of 12%. No more chasing down emails or wondering where a shipment was.

Predictive analytics was another game-changer. While I didn’t need a full AI system, even basic forecasting features helped me anticipate demand fluctuations and potential disruptions. For example, the system flagged a seasonal spike in raw material prices three months in advance, allowing me to lock in contracts at current rates and save over $15,000. These tools didn’t replace human judgment—they enhanced it. They provided data-driven insights that supported better financial decisions. Technology, when chosen wisely, isn’t an expense—it’s an investment that pays for itself through improved efficiency, reduced waste, and stronger financial control.

Risk Control: The Silent Wealth Builder

We often think of wealth creation as chasing growth, increasing sales, or expanding markets. But in my experience, the most powerful form of wealth preservation is risk control. You can’t build wealth if you’re constantly losing it to preventable disruptions. Supply chains are vulnerable to a wide range of risks—natural disasters, transportation failures, geopolitical tensions, supplier insolvencies, and even cyberattacks. These aren’t hypotheticals; they’re real threats that can wipe out profits in days.

I started treating risk management as a core financial discipline. I developed contingency plans for every critical node in my supply chain. For high-impact materials, I maintained safety stock at a secure offsite warehouse. I mapped out alternative shipping routes and identified backup logistics providers. I also reviewed my insurance coverage and customized it to reflect my cargo value, shipment frequency, and risk exposure. These steps didn’t generate immediate returns, but they provided peace of mind and financial protection.

Every quarter, I conduct a supply chain stress test—a scenario-based review that simulates disruptions like port closures or supplier bankruptcies. This exercise helps me identify weaknesses and update my response plans. For example, after one test revealed that two key components came from the same geographic region, I diversified sourcing to reduce concentration risk. These practices don’t eliminate risk, but they minimize its financial impact. Risk control is the silent engine of sustainable wealth. It doesn’t make headlines, but it keeps the business running when others falter. By proactively managing risk, I’ve turned potential disasters into manageable events—and that, more than any single investment, has safeguarded my business wealth.

Wealth Management Starts Before the Sale

Most entrepreneurs focus on the moment of sale as the point where value is created. But the truth is, financial strength is built long before that transaction occurs. Every decision in the supply chain—from sourcing raw materials to choosing a shipping method—shapes the profitability of every sale. A cheaper material might lower upfront costs, but if it leads to higher defect rates or customer returns, it erodes margins. A faster shipping option might improve delivery times, but if it drains cash flow, it weakens financial stability. I now evaluate every supplier, every contract, and every process through a dual lens: operational efficiency and financial impact.

This mindset shift transformed my business. I stopped seeing the supply chain as a cost center and started viewing it as a strategic asset. I aligned inventory levels with cash flow cycles, negotiated payment terms that supported liquidity, and built supplier relationships that reduced risk. I embraced technology that improved visibility and decision-making. And I prioritized risk control as a form of financial insurance. These changes didn’t require massive investments—they required discipline, clarity, and a long-term perspective.

Today, my supply chain doesn’t just support my business—it strengthens it. It protects margins, preserves cash, and enhances resilience. It has become a quiet but powerful engine for wealth preservation. I no longer fear disruptions the way I once did. Instead, I approach them with confidence, knowing that my systems are designed to absorb shocks and keep moving forward. For any entrepreneur looking to build lasting financial health, the lesson is clear: true wealth management begins not at the point of sale, but in the decisions made long before it. By mastering your supply chain, you don’t just run a smoother operation—you build a more valuable, more sustainable business.